Reverse Picking pulls a full License Plate from its storage Location and moves any extra items not needed for the Shipment to a separate License Plate to remain in storage. This occurs when the target License Plate to Pick from would have less remaining on it than would be Picked.

Prerequisites

- Outbound Order with an Order Class that has Reverse Pick enabled

- Released Wave

- Inventory in your Warehouse

Tip

If the Location assigned for the Pick no longer contains the Material for the Pick Task, you can press the F8 key to perform a Reallocation. See the Mobile Reallocation tutorial for more information.

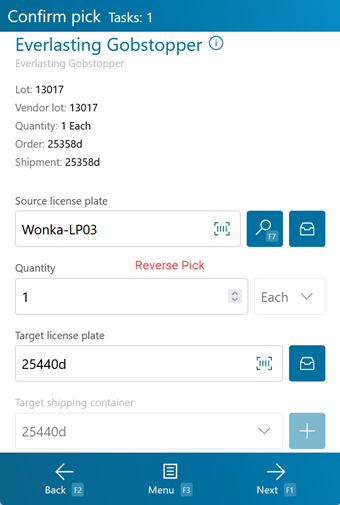

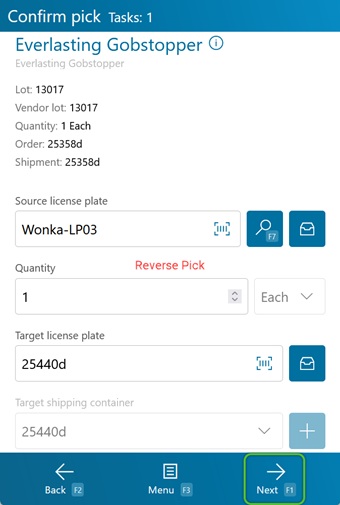

1. Scan or enter the Source License Plate. You can also tap or press F7 to have the system display all applicable License Plates in the Location.

Once the Source LP has been scanned, if the Quantity to be Picked is more than half the total number on the LP, the screen will change to reflect the Reverse Pick, displaying the words Reverse Pick in red - you will now be moving items from this License Plate to another Remaining License Plate that will stay in this Location.

2. Enter the Remaining Quantity to leave in this Location. Make sure the Packaging matches the expected Packaging.

3. Scan or enter the Remaining License Plate. You can create a new License Plate here, or select an existing one.

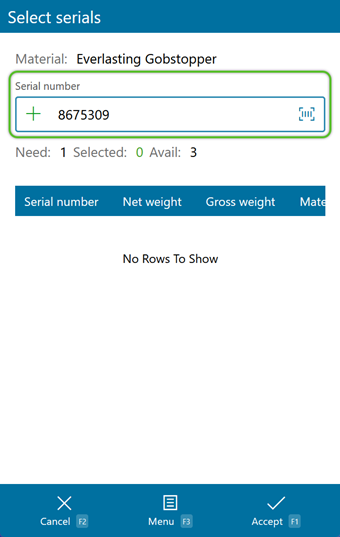

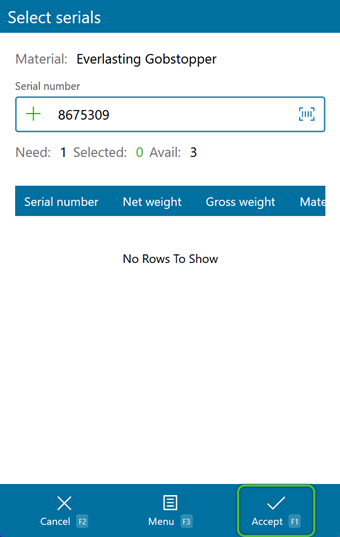

If your Material has individual Serial Numbers assigned to it, you will need to scan or enter them at this point.

1. You can either scan each individual Serial Number, or you can tap or press F8 to automatically select Serial Numbers for you.

Repeat this process for every Task that remains.

| Last Updated: |

| 06/06/2025 |